A transition & transformation program that I am currently involved in distinguishes performance management, capacity management and capacity planning as three different IT service management processes. The three ITSM processes are described separately and this results in a lot of design and documentation work, performed in isolation by different architects. I was asked by the project manager to look into the rationale for this distinction and assess its feasibility.

The three different concepts can best be explained by an analogy that everybody can relate to. I will use the analogy of a supermarket. The resources in the supermarket are the carts and baskets, the self-scanners, the tills and the cashiers. The users are the shoppers. The transactions are fetch a product and put it in the cart, scan all products from the cart and pay for all scanned products.

Performance management is defined as the process responsible for monitoring, analysing and reporting on response times and throughput. This process monitors the speed of the system and its services. In the analogy of the supermarket, this process keeps track of time spent in the shop and at the till by each shopper and of the number of shoppers that can be served per hour given a certain amount of available carts and open tills and the “processor speed” of the cashiers.

Capacity management is defined as the process responsible for monitoring, analysing and reporting on available resources and the utilisation of those resources. In the analogy of the supermarket this process keeps track of the amount of available carts, open tills and the queues per till. The “processor speed” of the cashier and the amount of purchases that they have to process have an influence too.

Capacity planning is defined as the process responsible for producing the capacity plan. In the analogy of the supermarket, the supermarkt manager will collect and analyse data about all above discussed parameters on a weekly or monthly basis and use that information to make decisions about the installation of extra manned tills or to invest in a self service scanning system so as to relieve the burden on the manned tills.

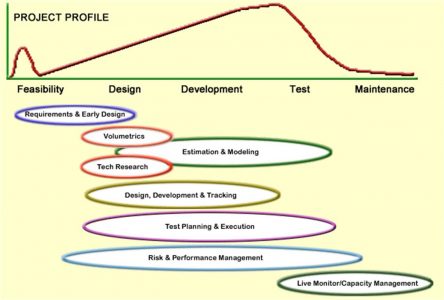

Although theoretically the ITIL capacity management process could be split into three separate processes as outlined above, it is not recommended to do this from a practical perspective. The many similarities and dependencies between the three “processes” point towards combining them into one “umbrella” process rather than to implementing them as three separate processes.

- The process flow for performance management is very similar to the process flow for capacity management. The sub-processes “analyse and model requirements”, “monitor, analyse and report”, “supervise tuning and performance / capacity delivery” are relevant in both cases.

- Performance management and capacity management both feed into capacity planning; capacity planning is entirely dependent on the other two. In ITUP “produce capacity plan” is therefore described as a sub-process of capacity management,

- Performance management, capacity management and capacity planning require similar skills. The roles involved in the three “processes” are mostly described as the capacity / performance manager, the capacity / performance administrator, the capacity / performance analyst. The first two roles are responsible for setting up and maintaining the capacity / performance framework and for streamlining the process as a whole. These roles are technology independent. The last role is not technology independent and can be implemented as a double-role for technology specialists in which case it is filled in by a multi-disciplinary team.

- Although the tools to monitor application and service performance are different from the tools to monitor infrastructure resource utilisation, it is recommended to correlate the metrics in the analysis of system performance. This is enabled by setting up a performance / capacity DataWareHouse in which all collected information is stored for analysis and reporting.

- In the case under discussion the team responsible for application performance reports into a different department than the team responsible for infrastructure performance and capacity but in order to meet the agreed service levels both teams will have to interface and cooperate closely in one process

Now let’s try to design the ideal performance / capacity management process for a retailer. First of all the demand as well as the service level requirements for performance have to be clarified.

Retailers know for each city where they have a shop how many customers they have on weekdays and in the weekend; they know the peaks in the year and on the day. Through their loyalty programs they know which customers buy which products. This is called the demand and the process keeping track of it is demand management. Demand management is focused on the business trends and patterns that influence performance and is in ITIL defined as a separate yet related process.

The service level requirements for performance may be different per customer. For the supermarket model that is used in the PEMMX classes the assumption was that all customers want to minimize their time in the supermarket and especially at the till, but this is not true for each customer. For instance my mother in law regards a visit to the nearby supermarket as a nice pastime. For her service and a friendly chat with the shop employees are more important than speed.

The simple supermarket simulation model that we used in our PEMMX classes allowed to specify variable input values for parameters such as the shopper arrival pattern, the number of available carts, the number of open tills. By playing with those parameters one can determine the optimal configuration of the shop given a certain shopper arrival pattern. This approach helps to forecast the effects of future demand and feeds into the capacity plan.

But the model needs to be calibrated based on real-life metrics. So we need a performance / capacity monitoring system in the shop that keeps track of the arrival pattern of the shoppers, the available carts and baskets, the available self-scanners, the open tills and the queues at each till. Let’s assume that a measurement system like that is possible – I don’t want to dive into the details of internet-of-things implementations in retail today – and that all measurements are collected and stored into a shop performance data warehouse.

I think eveybody agrees with me that in the retail example it does not make much sense to implement three isolated processes, one concerned with optimizing the time spent in the shop, one concerned with optimizing the amount, size and speed of resources such as carts, baskets, self-scanners, tills, cashiers and one concerned with planning for extra resources. It is more efficient to integrate the activities in these processes under one umbrella.